Coating Systems has been providing you with high-quality coatings and streamlined coating processes since 1975. Read on to discover the different services we offer and why you should choose Coating Systems for all your industrial coatings and processes.

Coating Systems offers custom coating services and formulations to meet the needs of any commercial and industrial application. We specialize in rubber coatings, dip-spin applications, and wet-dry custom applications. We can coat any metal and rubber product with custom-engineered formulations of wet spray, electrostatic powder, fluidized bed powder, and dip-spin coating.

Some of the benefits of customized coating include aesthetic and functional advantages over your competitors, improved individual/bulk processing applications, high conductivity with the right materials, the proper coating for exotic or unusual materials, and much more. Find out more about the custom coating services at Coating Systems.

Coating Systems, Inc. has developed a comprehensive portfolio of advanced services to meet the high standards of our customers. Review the wide range of services provided by Coating Systems, Inc.

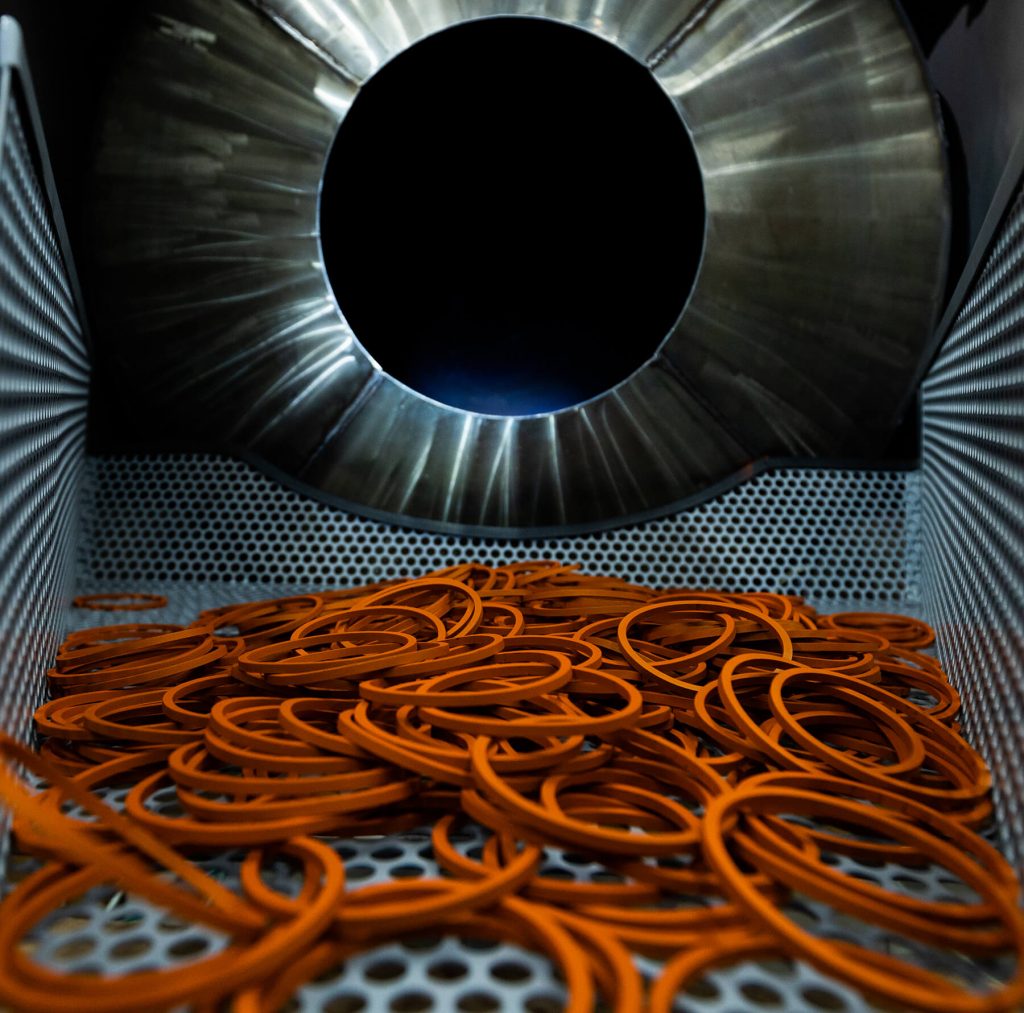

Coating Systems provides custom o-ring coating services with PTFE dry film lubricants, including Xylan, Emralon Tm001, and Molykote. We used advanced systems to precisely control the details of coating formulation, droplet size, pattern of spray, temperature, tumble speed, and more.

Fluoropolymer is a polymer that is based in fluorocarbon and has strong carbon-fluoride bonds. Custom fluoropolymers can be formulated to resist corrosion, stand up to acids, and create a non-stick surface.

Dry and solid lubricants offer permanent lubrication to withstand extreme pressure while improving conductivity and much more. Take advantage of faster production times, anti-galling coatings, and anti-aging properties for machinery parts.

Dip-Spin is a process whereby the product is placed in a mesh basket, submerged in a coating solution, and spun to remove the excess coating. We customize our process and formulations to achieve precise, highly repeatable results for coating services.

High-quality sandblasting prepares the surface you are coating for long-lasting application, optimal properties, and ideal aesthetics. Professional abrasive blasting improves the process and the finished product, for a reliable, cost-effective coating solution.

Over time, environmental conditions can cause metals like iron and steel to oxidize and form rust. Coating Systems, Inc. offers a wealth of industrial painting options that prevent the unwanted side-effects of wear, tear, and weather.

Powder coating is an optimal solution for commercial and industrial applications, such as heavy equipment, presses, shears, pedestals, and vehicles. Coating Systems is a leader in powder coating solutions for the largest applications, with an oven opening of 15’ x 12’ and advanced custom coating formulations.

Coating Systems, Inc. offers precise Visual Inspection Services to identify and address any defects, inconsistencies, or quality issues. We are dedicated to excellence, and that’s why we provide experienced visual inspection services.

Coating Systems, Inc. has developed a comprehensive portfolio of advanced services to meet the high standards of our customers. Review the wide range of services provided by Coating Systems, Inc.

Coating Systems provides custom o-ring coating services with PTFE dry film lubricants, including Xylan, Emralon Tm001, and Molykote. We used advanced systems to precisely control the details of coating formulation, droplet size, pattern of spray, temperature, tumble speed, and more.

Fluoropolymer is a polymer that is based in fluorocarbon and has strong carbon-fluoride bonds. Custom fluoropolymers can be formulated to resist corrosion, stand up to acids, and create a non-stick surface.

Dry and solid lubricants offer permanent lubrication to withstand extreme pressure while improving conductivity and much more. Take advantage of faster production times, anti-galling coatings, and anti-aging properties for machinery parts.

Dip-Spin is a process whereby the product is placed in a mesh basket, submerged in a coating solution, and spun to remove the excess coating. We customize our process and formulations to achieve precise, highly repeatable results for coating services.

High-quality sandblasting prepares the surface you are coating for long-lasting application, optimal properties, and ideal aesthetics. Professional abrasive blasting improves the process and the finished product, for a reliable, cost-effective coating solution.

Over time, environmental conditions can cause metals like iron and steel to oxidize and form rust. Coating Systems, Inc. offers a wealth of industrial painting options that prevent the unwanted side-effects of wear, tear, and weather.

Powder coating is an optimal solution for commercial and industrial applications, such as heavy equipment, presses, shears, pedestals, and vehicles. Coating Systems is a leader in powder coating solutions for the largest applications, with an oven opening of 15’ x 12’ and advanced custom coating formulations.

Coating Systems, Inc. offers precise Visual Inspection Services to identify and address any defects, inconsistencies, or quality issues. We are dedicated to excellence, and that’s why we provide experienced visual inspection services.

At Coating Systems, we strive to create custom formulations to help you reach new milestones, create new products, make your existing products last longer, increase productivity, and decrease operating costs. If you’re looking for an experienced custom coating provider, get in touch with us today!