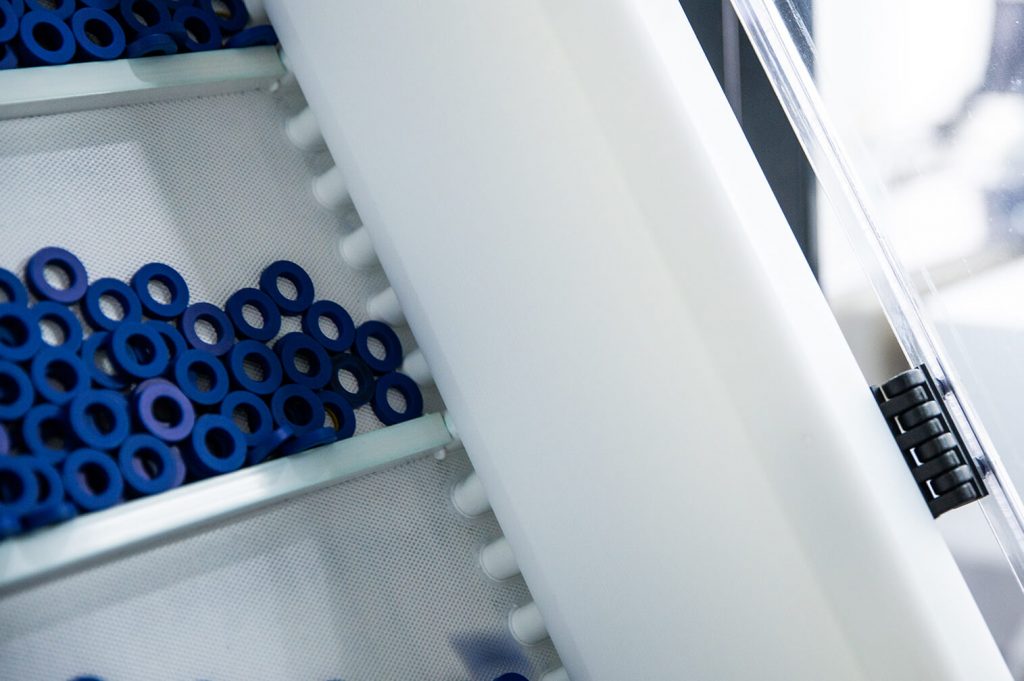

Coating Systems provides o-ring coating services that focus on dry film lubricants. Common dry film lubricants used at Coating Systems include Xylan, Emralon Tm001, and MOLYKOTE®. These coatings make it possible to color-code your o-rings, allowing for easy identification. Our high-quality coatings allow your industrial processes to run for longer periods with fewer breakdowns. Discover details about static and dynamic seals, common dry film lubricants, and some frequently asked questions about coating options offered at Coating Systems.

Static seals, as their name implies, are o-rings set in place to perform a single function. Dry film lubricant coatings help these o-rings slide easily into place because it reduces the insertion force.

Because dry film lubricant coatings do not form a chemical bond to the base substrate of the o-ring itself, but rather adhere to it like a glue, they should not be considered permanent. Dry film lubricant coatings must be replaced from time to time. Even so, they will dramatically increase the life of your static seal o-rings.

Unlike static sealing o-rings, dry film lubricants for dynamic sealing o-rings are made with motion in mind. The aim of applying dry film lubricants to dynamic seals is to extend the life of seals that are rubbed, compressed, and abused due to reciprocating, rotating, or oscillating motions. Dry lubricants for dynamic seals, such as MOLYKOTE®, are designed to rub off onto the other components they come into contact with. This process lubricates both the o-ring surface and whatever it touches.

It is important to note that these coatings do not enhance the chemical resistance of your o-rings, so they may not be able to withstand the same exposures as reliably as the base compound of the ring itself. Some things can be done to promote coating adhesion, such as washing to remove mold release or contaminants or post-curing.

No. Thicker applications will crack and flake. If you are receiving complaints about the lifespans of your o-rings, remember that the job of the coating is to help identify the part and to help it ease into place.

Our process is proprietary, but we can share some key details with you.

Our coating application process takes place in an ambient environment. It is a bulk coating process that allows for batches of hundreds of seals to run in each batch. Within 24 hours of coating, we cross-link and cure items in ambient temperatures. Finally, we are able to accelerate cross-linking or curing by performing an additional bake at 220° – 350°F, depending on the compound and the coating material.

Coating Systems, Inc. has been serving customers for more than 40 years, and we’re happy to help with your coating needs for o-rings, too. If you have questions, please call us at 1-367-5600 or let us provide you with free samples of our work.