When we think dry film lubrication with amazing corrosion resistant properties, CSI thinks Sandstrom! Recognized for meeting tough military specifications, by using Sandstrom’s technologies, CSI can assist your business by applying coatings that are geared strictly toward performance.

CSI can provide the following Sandstrom coatings, and military specifications where available

- 9A-AS5272C TYPE II (formerly MIL-L-46010 TYPE II)

- 099-AS5272C TYPE III-MIL-PRF-46010 G (formerly MIL-6–46010 TYPE III)

- LC-300-AS5272C TYPE I (formerly MIL-L-46010 TYPE I)

- 28A-MIL-PRF 46147D

- Hi-T 650-PWA550V

- #329-MIL-PRF-81329D

Specifications:

9A-AS5272C TYPE II

Product Description

Sandstrom 9A dry film lubricant is a paint-like coating containing molybdenum disulfide and corrosion inhibiting pigments. This heat curing material prevents corrosion, galling, seizing and fretting. It is a low-friction coating which exhibits long wear life when operated at -320°F to +500°F under loads exceeding 100,000 psi. Sandstrom 9A should be applied where maximum wear life and corrosion protection from a dry film lubricant are required.

Sandstrom 9A may be applied by brush, dip or spray method to a wide variety of surfaces. After it is heat cured, 9A is virtually unaffected by atmospheric and fretting corrosion, solvents, acids, oils or degreasers and is not re-softened at elevated temperatures.

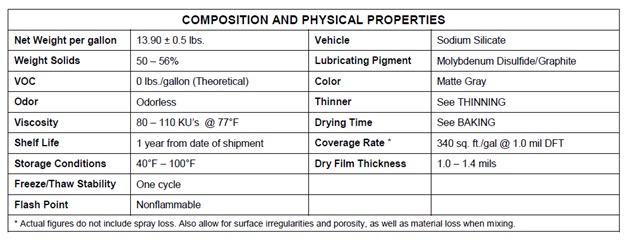

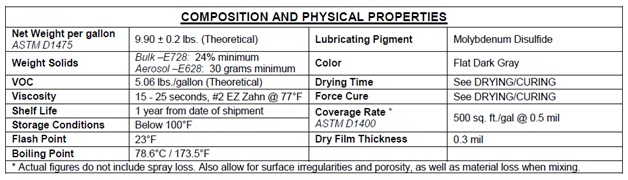

Product Specifications

[hr]

099-AS5272C TYPE III-MIL-PRF-46010

Product Description

Sandstrom #099 dry film lubricant is a paint-like coating containing molybdenum disulfide and corrosion inhibiting pigments. This heat curing material prevents corrosion, galling, seizing, and fretting. It is a low-friction coating that exhibits long wear life when operated at -320°F to +500°F under loads exceeding 100,000 psi. Sandstrom #099 should be applied where maximum wear life and corrosion protection from a dry film lubricant are required.

Sandstrom #099 may be applied by brush, dip or spray method to a wide variety of surfaces. After it is heat cured, #099 is virtually unaffected by atmospheric and fretting corrosion, solvents, acids, oils, degreasers and is not re-softened at elevated temperatures.

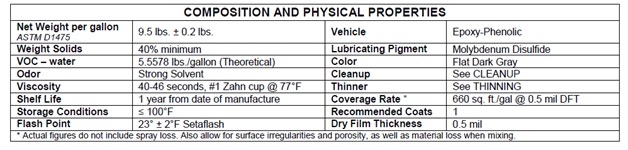

Product Specifications

[hr]

LC-300-AS5272C TYPE I

Product Description

Sandstrom LC-300 is a lead free lacquer-like dry film lubricant coating containing molybdenum disulfide and corrosion-inhibiting pigments. This Heat Curing material prevents corrosion, galling, seizing and fretting. It is a low-friction coating that exhibits long wear life when operated at -320°F to +400°F under loads exceeding 100,000 psi.

LC-300 may be applied by brush, dip or spray method. After it is heat cured, LC-300 is virtually unaffected by atmospheric and fretting corrosion, solvents, acids, oils and degreasers and is not re-softened at elevated temperatures.

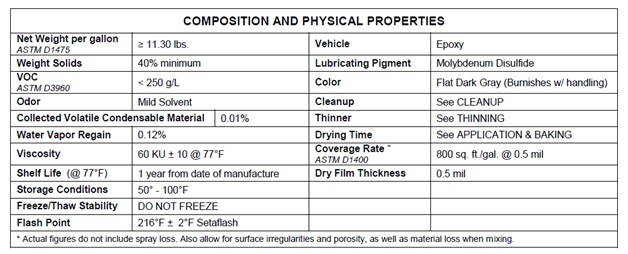

Product Specifications:

[hr]

28A-MIL-PRF 46147D

Product Description

Sandstrom 28A Solid Film Lubricant is a lacquer-like coating containing molybdenum disulfide and corrosion inhibiting pigments. This air drying material prevents corrosion, galling, seizing and fretting. It is a low-friction coating that exhibits long wear life when operated at -320°F to +300°F under loads exceeding 100,000 psi. Sandstrom 28A should be applied where baking with the longer wearing, heat cured #099, Sandstrom 9A or LC-300 is not desirable or practical.

Once 28A has been applied to a properly prepared surface and allowed to cure, it is virtually unaffected by atmospheric and fretting corrosion, solvents, acids, oils and degreasers. Sandstrom 28A can be applied to all metallic and non-metallic surfaces by spray application.

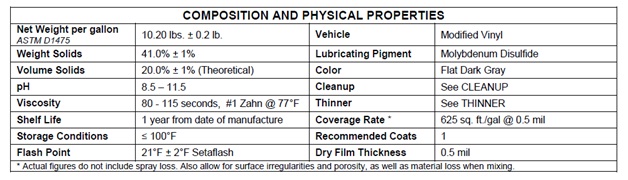

Product Specifications:

[hr]

Hi-T 650-PWA550V

Product Description

Sandstrom HI-T 650 Solid Film Lubricant is a lacquer-like coating containing molybdenum disulfide and corrosion-inhibiting pigments with a silicone vehicle. It is a specialized product designed to prevent galling and provide long wear life at high temperatures (500°F to 750°F) exceeding the operational ranges of Sandstrom 9A and 28A.

Higher pigment loading protects all metals from galling, fretting, and seizing. This solid film lubricant exhibits extremely low friction and anti-galling characteristics at loads in excess of 100,000 psi. It may be applied by spray or dip. Complete application instructions are on the reverse of this sheet.

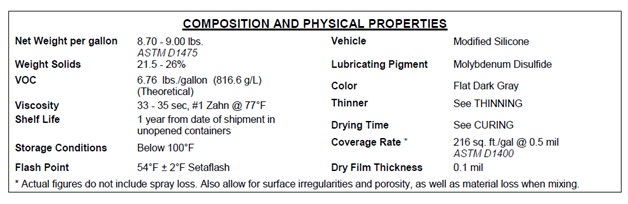

Product Specifications

[hr]

#329-MIL-PRF-81329D

Product Description

Sandstrom #329 is a single component, waterborne, inorganic heat-curing coating that may be applied to a wide variety of metals. It is intended for use on components that will operate in environments where properties of organic materials are not desired.

Product Specifications