Fluoropolymer coatings, also known as fluoroplastic coatings, can help your industrial equipment last longer by creating a durable layer between the actual structure of the equipment and whatever environment is directly on the outside. These highly durable and corrosion-resistant coatings provide unbeatable protection for industrial equipment and components that must withstand harsh conditions and the environment in general.

We answer the most frequently asked questions about fluoropolymer coatings and how they can benefit your industrial equipment.

What Are Fluoropolymer Coatings?

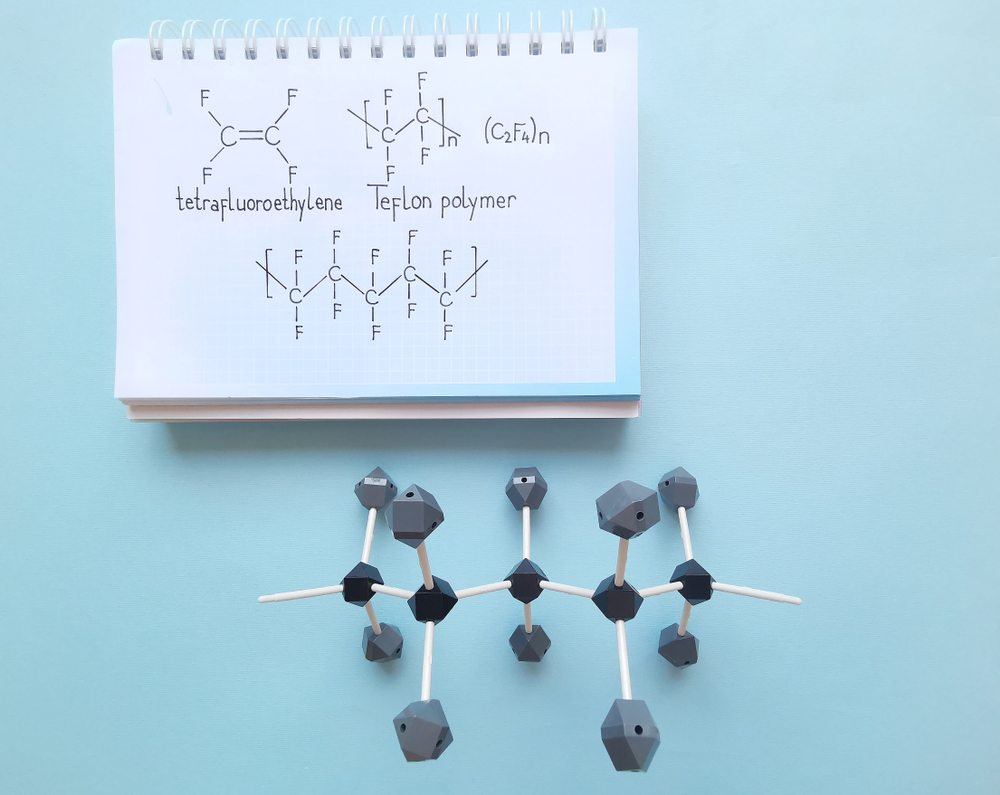

Fluoropolymer coatings are a type of industrial coating that offers exceptional protection and durability for various substrates. Rather than chains of hydrocarbons found in organic molecules like methane, ethane, and others, chemical engineers replace the hydrogen with fluorine, giving them unique properties.

One of the main advantages of fluoropolymer coatings is their exceptional corrosion resistance, making them an ideal choice for equipment exposed to harsh environments or corrosive substances. Whether it’s outdoor equipment, chemical processing plants, or infrastructure in coastal areas with salt water, fluoropolymer coatings provide a reliable barrier against corrosion.

Fluoropolymer coatings are known for their nonstick properties. They can prevent the build-up of contaminants such as dirt, oil, or chemicals on the coated surface. The nonstick properties of fluoropolymer coatings make them ideal for applications where cleanliness and ease of maintenance are crucial, such as food processing equipment or medical devices.

Thermal stability is another reason to invest in fluoropolymer coatings. They can withstand extreme temperatures, anywhere from cryogenic temperatures up to 500 degrees Fahrenheit, without losing their protective properties, so they’re suitable for applications where temperature fluctuations are common, such as automotive parts, electrical components, industrial machinery, underwater applications, and aerospace parts.

What Applications are Best Suited for Fluoropolymer Coatings?

Fluoropolymer coatings are incredibly versatile and can be applied to various substrates, making them suitable for multiple applications.

1. Industrial Equipment

Fluoropolymer coatings are commonly used in industries such as chemical processing, oil and gas, and manufacturing. Their corrosion resistance and nonstick properties make them ideal for coating tanks, pipes, valves, and other equipment that are exposed to corrosive substances or require easy maintenance.

2. Automotive

The automotive industry can significantly benefit from fluoropolymer coatings. These coatings can be applied to engine components, exhaust systems, and brake lines. The durability and thermal stability of fluoropolymer coatings help protect these parts from extreme temperatures and corrosive elements, improving their performance and longevity.

3. Food Processing

Fluoropolymer coatings are an essential component of food processing equipment where cleanliness and hygienic processes are necessary. These coatings prevent the build-up of contaminants on surfaces. From mixing bowls to conveyor belts, fluoropolymer coatings play a vital role in maintaining food safety and quality standards.

4. Medical Devices

The medical industry relies on fluoropolymer coatings for their nonstick properties and biocompatibility. These coatings are commonly used on surgical instruments, medical implants, and lab equipment, where cleanliness, ease of sterilization, and chemical resistance are crucial to healthy patient outcomes.

What Should I Consider Before Investing in a Fluoropolymer Coating?

When choosing a suitable fluoropolymer coating for your equipment, there are several factors to consider.

First, assess the specific needs and requirements of your equipment. Think about the environment your equipment will be exposed to and the level of protection it will require. Fluoropolymer coatings offer exceptional corrosion resistance, nonstick properties, and thermal stability, but you need to ensure that these qualities align with your equipment’s needs.

Additionally, consider the substrate you’ll be coating. Fluoropolymer coatings can be applied to many materials, including metals, plastics, and ceramics. However, different substrates may require specific surface preparation techniques or primer coats to ensure proper adhesion of the surface coating.

Examine the performance requirements of your equipment. Determine the necessary coating thickness, flexibility, and abrasion resistance based on the specific demands of your equipment. Knowing the parameters of your equipment ensures that the fluoropolymer coating can withstand the conditions it will be exposed to and provide long-lasting protection.

Research expertise and reputation of the coating supplier or applicator. It’s essential to choose a company, like Coating Systems, with expertise in applying fluoropolymer coatings and a track record of delivering high-quality results. They should be able to guide the best type of coating for your industrial equipment while installing the coatings properly for the best results.

What Is the Application Process for Fluoropolymer Coatings?

Applying fluoropolymer coatings to your industrial equipment requires a precise and careful application process. While it is recommended to consult with a professional coating company for the best results, here is a general overview of the application process for fluoropolymer coatings.

1. Surface Preparation

Before applying the fluoropolymer coating, the surface must be thoroughly cleaned and prepared. Cleaning typically involves removing any dirt, rust, oils, or previous coatings that may be present. Surface preparation techniques may include abrasive blasting, chemical cleaning, or mechanical methods.

2. Priming the Substrate (if necessary)

Depending on the substrate being coated, a primer may be required to ensure proper adhesion of the fluoropolymer coating. The primer creates a strong bond between the substrate and the fluoropolymer coating, improving its performance and longevity.

3. Mixing and Application

The fluoropolymer coating typically starts as a two-part system that needs to be mixed. Once mixed, the coating is applied using a specialized spray bottle, brush, or roller.

4. Curing

After application, the coated surface must undergo a curing process to achieve its optimal properties. Curing allows the coating to dry and cure at the recommended temperature and time to maximize its protective benefits.

How Can I Ensure the Longevity of My Fluoropolymer-Coated Equipment?

After application by a professional industrial coating company, you can prolong the life of your industrial equipment with regular maintenance and inspections. Periodically check for any signs of damage, such as chipping, cracking, or peeling. Promptly address any issues to prevent further deterioration or potential loss of protection.

Be mindful of the environment your coated equipment will be exposed to. While fluoropolymer coatings offer excellent resistance to corrosion, you should still minimize exposure to extreme conditions whenever possible. Take precautions to prevent prolonged exposure to high temperatures, chemicals, abrasive materials, or other factors that may accelerate wear and tear, if possible.

What Are Some Common Issues With Fluoropolymer Coatings, and How Can I Address Them?

One common issue with fluoropolymer coatings comes from chips or cracks in the surface. They can happen due to impact or excessive force on the coated surface. To address this issue, inspect your coated equipment regularly and promptly address any chips or cracks that you find.

Fluoropolymer coatings may also experience fading or discoloration over time, especially when exposed to UV radiation. Consider choosing a fluoropolymer coating with enhanced UV resistance. Additionally, regular cleaning and maintenance can help preserve the appearance of your coated industrial equipment and prevent discoloration.

Who Can Apply Fluoropolymer Coatings to My Industrial Equipment?

Coating Systems has decades of experience with fluoropolymer coatings, and we can apply these high-quality coatings to industrial equipment if it is ideal for you. Contact us or call (513) 367-5600 for more information.