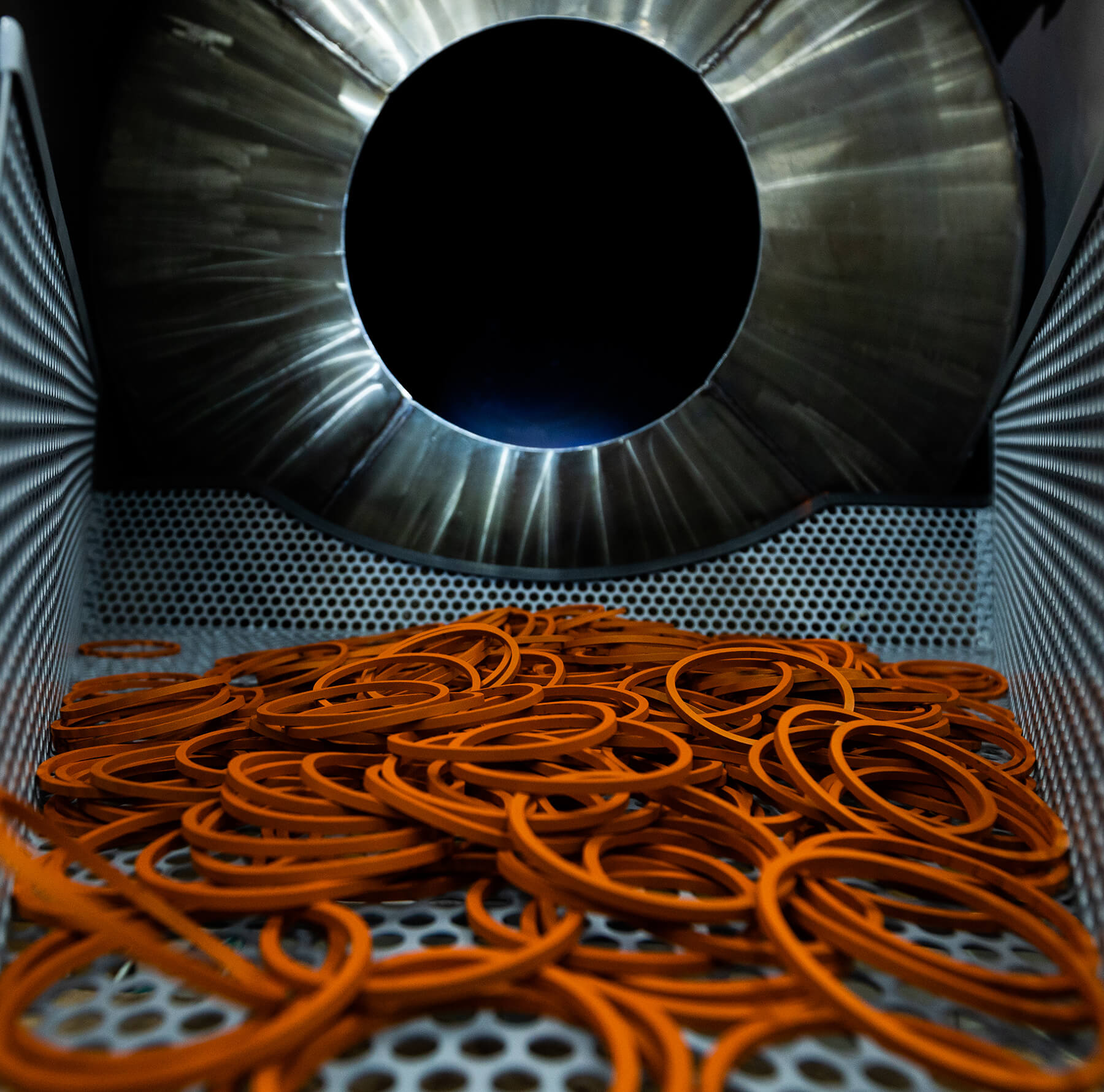

Coating Systems specializes in applying coatings to various items, from O-rings to industrial equipment and pipes to trailers.

Coating O-rings is one of our specialties! We can help improve the longevity of your parts and industrial equipment with our dry film lubricants for these vital pieces of your assemblies.

Read on to find answers to some frequently asked questions about O-ring coatings.

What do you coat O-rings with?

O-ring coatings run the gamut, from simple soap and water to petroleum distillates and dry film lubricants. It depends on the application the O-rings are used for. You might need a different lubricant for a food production facility versus an off-shore petroleum rig.

Industrial coatings for O-rings include:

- PTFE

- Xylan

- Emralon Tm001

- MOLYKOTE®

Why do you need O-ring coatings?

There are many benefits from O-ring coatings, such as:

- Increased safety, service life and functionality of O-rings (and hence your equipment).

- Fewer breakdowns caused by O-rings.

- Longer times between maintenance on items with O-rings.

- Reduction of coefficient of friction, wear, abrasion, damage, and scuffing.

- Decreased leakage by filling minuscule gaps between surfaces and the O-ring seal.

Why do companies use dry film lubricants for O-ring coatings?

The goal of applying a dry film lubricant to an O-ring is to protect your O-ring from:

- Resistance

- Compression

- General wear and tear

Dry film lubricants are designed to rub off onto the component that the O-ring will come in contact with, thereby lubricating the O-ring and the contact surface simultaneously during use.

Why are different colors used for O-rings?

Companies use different colors for O-rings for different reasons, including:

- To distinguish one material from another on a production line. This is particularly important when trying to clean machinery or ascertain where possible breakdowns are coming from.

- To improve visibility of equipment. If your technicians require a quick way to determine what the equipment is or a type of feeder line, seeing a particular color offers an efficient protocol for identifying the equipment.

- Better appearance of equipment. Sometimes, companies simply want O-rings to stand out from the background colors of the equipment. Bright colors against dark backgrounds help staffers see where the O-rings are on the line without having to do a lot of searching.

How do you condition an O-ring?

You can condition an O-ring by adding a lubricant to it manually or by using dry film lubricants that work automatically during the machine’s operation.

What company offers O-ring coating services?

Coating Systems, based in Harrison, Ohio, and Greater Cincinnati, offers powder coating on any items with high-quality finishes to meet your precise specifications.

Call us today at 1-800-593-7754 or contact us online.