The great thing about XYLAN coatings is that they are available in virtually any color and can actually be custom matched to your pantone or RAL color standard requirements. CSI has been using Whitford coatings for at least 20 years and will continue to do so. Whether it’s offshore hardware requiring an anti-seize fluoropolymer coating or an FDA compliant release coatings for the food industry, CSI can select and apply the perfect Whitford Coating to meet and exceed your needs.

Inventory:

Specifications:

Xylan –

Product Description

Description: Xylan is generally used to reduce friction, improve wear resistance, and for non-stick applications. Additionally, it can be used to protect a metal from corrosion. The most commonly known application is in non-stick cookware but Xylan coatings have also been used extensively in the automotive industry and for corrosion protection in the oil and gas industry.

Product Specifications

| Tensile Strength (ASTM D1708) | 4000 – 5000 psi |

| Elongation (ASTM D4894) | 50% |

| Impact Strength (ASTM D256) | 13 ft – lb/in |

| Hardness (ASTM D2240) | 60 – 90 HB (shore D) |

| Abrasion Resistance (Tabor) | > 15 mg |

| Coefficient of Friction (ASTM D1894) | .15 – .35 static |

| Dielectric Strength (ASTM D149) | 1400 volts per mil |

| Use Temperature | -100°F to 500°F max |

| Melting Point | n/a |

| Thermal Conductivity | n/a |

| Chemical Resistance (ASTM D543) | good |

| Salt Spray Resistance (ASTM B117) | excellent |

| Water Absorption (ASTM D570) | < .03 % |

| Thickness | .0008″ – .002″ |

[hr]

Quantum –

Product Description

Quantum2 is internally reinforced with a special blend of diverse ceramic materials. It provides a wider window of application tolerances and is more “user friendly”. While the adhesion remains outstanding, Quantum2 has a smoother surface appearance and has high gloss. In addition, this system has superb abrasion resistance and outstanding nonstick performance.

Product Specifications

Not Applicable.

[hr]

Xylan 1010 –

Product Description

Whitford’s first product was Xylan 1010, a coating which enjoyed immediate acceptance as an engineering material. Today, Xylan 1010 is still the most versatile, most dependable, most successful industrial fluoropolymer coating in the world.

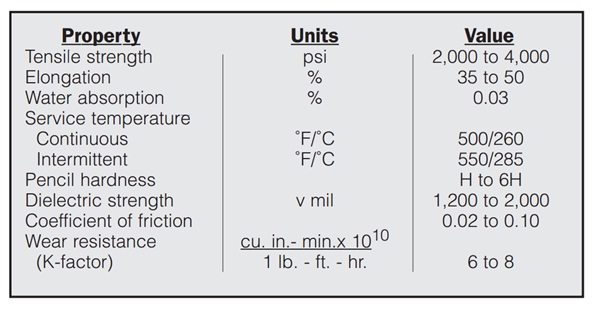

Product Specifications

[hr]

Xylan 1014 –

Product Description

Compared to Xylan 1010, Xylan 1014 fastener-class coatings contain significantly more bonding resin relative to its content of PTFE lubricant. Altering the formula in this manner produces finishes which are harder, more abrasion-resistant, glossier, and less porous. Frictional values remain low and very predictable.

Product Specifications

Not Applicable

[hr]

Xylan 333 –

Product Description

Not Applicable

Product Specifications

Not Applicable

[hr]

Xylan 1661 –

Product Description

A fluoropolymer coating for electrodeposition masking for the automotive industry; meets GM 6076M.

Product Specifications

Not Applicable

[hr]

Xylan 1220 –

Product Description

Similar in composition to the 1000 Series, it has excellent chemical resistance and the ability to “work” at elevated temperatures. There are two principal distinctions between 1220 and its 1000 Series cousins: fluorinated ethylene propylene (FEP) replaces PTFE as the low-friction polymer and the carrier is a water/solvent blend rather than 100% solvent. These changes in chemistry yield a dry film with enhanced non-wetting and nonstick characteristics and, compared to Xylan 1010, a cost saving of at least ten percent. Xylan 1220 may be applied via dip-spin or conventional air spray, adding to its utility.

Product Specifications

Not Applicable

[hr]

Xylan 1424 –

Product Description

Fastener-class coating material that is a waterborne/VOC-compliant, resin-bonded, thermally cured, single-film, dry lubricant. It is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up torque.

Product Specifications

Not Applicable

[hr]

Xylan 1427 –

Product Description

Extreme corrosion and chemicalresistant coating that is also a waterborne/VOCcompliant, resin-bonded, thermally cured, singlefilm, dry-film lubricant. Primarily formulated for use on fasteners to prevent attack from a broad spectrum of chemicals and corrosives. Provides extra corrosion protection while retaining all attributes associated with a composite coating.

Product Specifications

Not Applicable.