Unfortunately, industrial machinery is prone to wear and breakdown. Wear and tear is so common there’s an entire field of study, tribology, dedicated to it.

Tribology recognizes six common types of wear: adhesive wear, abrasive wear, surface fatigue, fretting wear, erosive wear, and corrosion and oxidation wear.

Related Post: Industries that Commonly Use Xylan

Xylan is an excellent option for reducing wear and tear in industrial settings. We’ll share how this dry-film lubricant reduces six common types of manufacturing wear.

Adhesive Wear

Adhesive wear occurs when surfaces that come into contact and produce friction begin to produce debris from the wear.

This debris results from the “asperities” on each surface, the microscopic rough edges on the surface of what may appear to the eye as smooth metal.

Xylan coatings prevent adhesive wear by filling in asperities and creating a smoother metal surface, yielding less friction, debris, and wear.

Related Post: A Look at Some of the Multiple Benefits of Xylan

Abrasive Wear

Abrasive wear is the process of materials wearing down by the repetitive action of abrasive particles rubbing against the surface.

This wear is similar to adhesive wear, except rather than both surfaces losing material, the softer material is “plowed” over by the more rigid surface. Xylan coatings keep abrasive wear to a minimum, increasing the overall lifespan of whatever surfaces come into contact.

Surface Fatigue

Surface fatigue refers to cracks on a material’s surface caused by cyclic loading. By evening out surface asperities, Xylan coatings allow pressure to be evenly distributed, reducing wear over time.

Fretting Wear

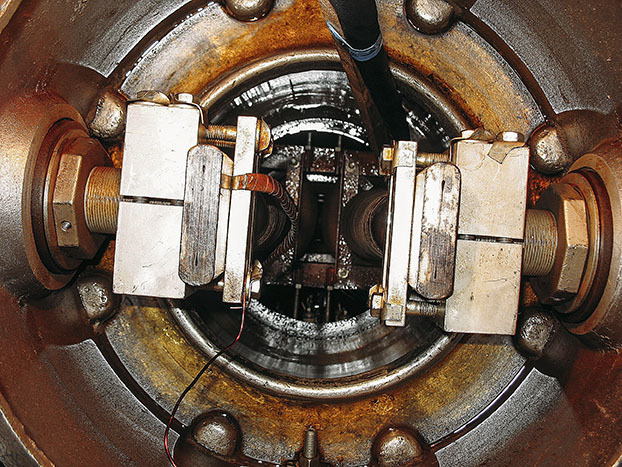

Fretting is the gradual wear or damage that occurs at the contact surfaces between two materials due to small, repetitive movements or vibrations. Fretting is most common in bearings and can be further worsened by lost material oxidizing, becoming hard, and causing further damage.

Xylan is resistant in particularly harsh environments that involve extreme temperatures and can be used where other lubricants cannot perform.

Erosive Wear

Erosive wear is the wearing away of material due to the impact of solid particles or fluids carrying abrasive particles. Think of it as a brief sliding motion occurring when the particle strikes the surface.

As you can imagine, in the case of sandblasting, that small but repeated contact can put a dramatic strain on a surface. This kind of wear is prevalent in piping systems.

Related Post: Coating Systems Explores the Damage Done by Friction

Xylan coatings fill in tiny crevices between the asperities, allowing for a smoother surface that will not wear as quickly.

Corrosive/Oxidative Wear

These types of wear occur when chemicals come into contact with a surface, causing materials to break down by chemical reaction.

Xylan coatings protect surfaces from corrosive materials, like seawater on offshore oil rigs.

Xylan Dry Film Lubricant from Coating Systems, Inc.

If you notice that your machines are experiencing more wear and even breaking down more frequently than they should, it could be time to consider dry film lubricants such as Xylan.

If you have questions about the process or are ready to let Coating Systems work for you, call us at 513-367-5600!