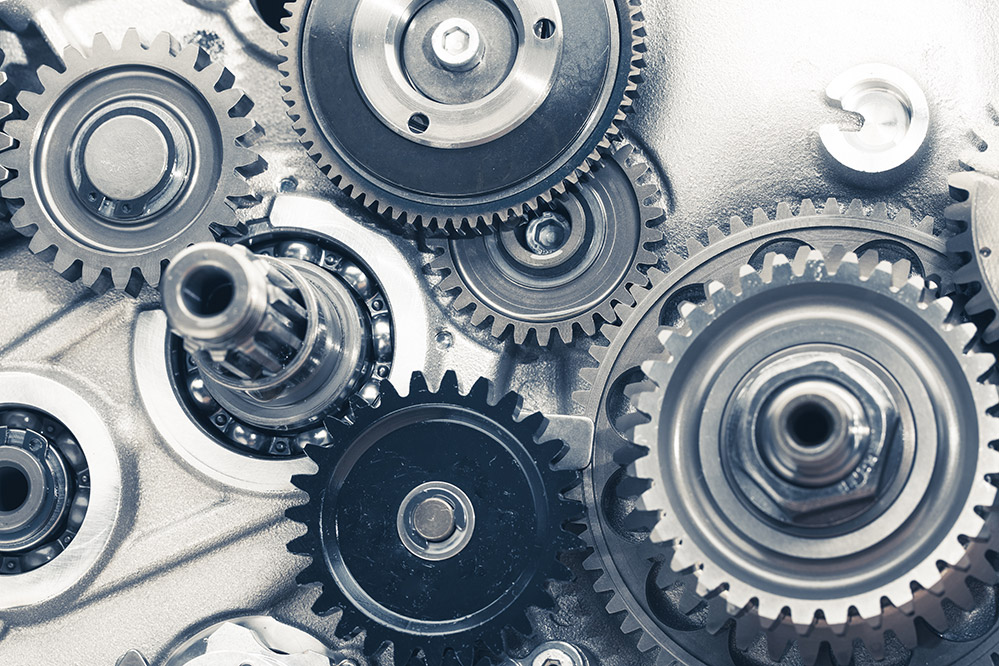

At Coating Systems, Inc., we know that metal machine parts require a frictionless coating to prevent the parts from rubbing together. When metal machine parts rub together, they create high amounts of friction. Too much friction causes machine parts to stick together, which, overtime, can damage the entire machine. Metal sticking together because of friction is known as seizing. To prevent seizing from occurring, Coating Systems, Inc. uses frictionless o-ring coatings, also known as anti-seize coating. Here, we explain the need for frictionless o-ring coating and how it can save you time and money.

Cost and Maintenance of Seizing

Even the smallest parts of a machine can create costly problems when seizing occurs. If small parts seize, they can cause damage to larger parts and critically damage the entire machine. When repairs are put off, the perpetuating cycle of friction and damage can result in the need to replace the entire piece of machinery. To avoid these high costs, continuous maintenance, such as coating your machine parts, is vital. Anti-seize coatings, such as high-quality dry film lubricant, minimize friction between machine parts and prevent seizing from occurring. Using an anti-seize coating will ultimately save you time and money.

Related Post: Here Are Some Common Applications Of MOLYKOTE®

At Coating Systems, Inc., our design team works closely with you to provide the best frictionless coating for your O-rings and other machine parts. We strive to create a durable coating which delays or prevents large amounts of friction from occurring. This gives you time to replace parts at normal intervals in a cost-effective way.

How Anti-Seize Coating Works

Frictionless coatings are different than basic anti-corrosion coatings, such as Xylan, Emralon, and Tm001. At Coating Systems, Inc., our anti-seize coatings incorporate a durable film which helps machine parts run smoothly together. Similar to oiling a bike chain or waxing a surface, our anti-seize coating provides a similar effect, keeping metal smooth so that it slides easily together instead of catching and grating on surrounding materials. By regularly coating your machine parts, you ensure that your machine runs longer.

Related Post: A Look at Some of the Multiple Benefits of Xylan

Contact Coating Systems Inc.

For more information on anti-seize, frictionless O-ring coatings, and other coatings offered by Coating Systems, Inc., contact us today. With over 40 years of experience in coating, our knowledgeable staff will work with you or your in-house design team to deliver satisfactory customer service and products every time. Whether you require rubber O-ring coating, industrial painting, dip-spin coating, or something completely custom, we are happy to help.