Sealing solutions are vital for industrial machinery. Seals keep machinery running smoothly and extend their lifespan. When not taken care of properly, industrial machinery can lose years of functional life, costing your business money in the long run.

O-rings and lathe-cut gaskets are two standard solutions for creating a tight and effective seal. Both prevent leakage and provide sealing solutions, but they have distinct differences in design, application, and performance.

Related Post: Coating Systems Reveals Inventions Made Possible by O-Rings

Finding the right gaskets and sealing solutions for your machinery is a significant part of that process. Today, Coating Systems explores the critical differences between O-rings and lathe-cut gaskets to help you make informed decisions that ensure the longevity and efficiency of your sealing system.

What Are The Differences?

In many ways, O-rings and lathe-cut gaskets serve the same purpose. They are both sealing devices that can absorb pressure while preventing leaks.

However, a common misconception about these two devices that often leads to misapplication is that they are the same. While they do share similarities, they also have significant differences.

The shape of an O-ring is different from that of a lathe-cut gasket and is made of different materials. There are specific instances when these devices should be used and shouldn’t be thought of as one and the same.

What Are O-Rings?

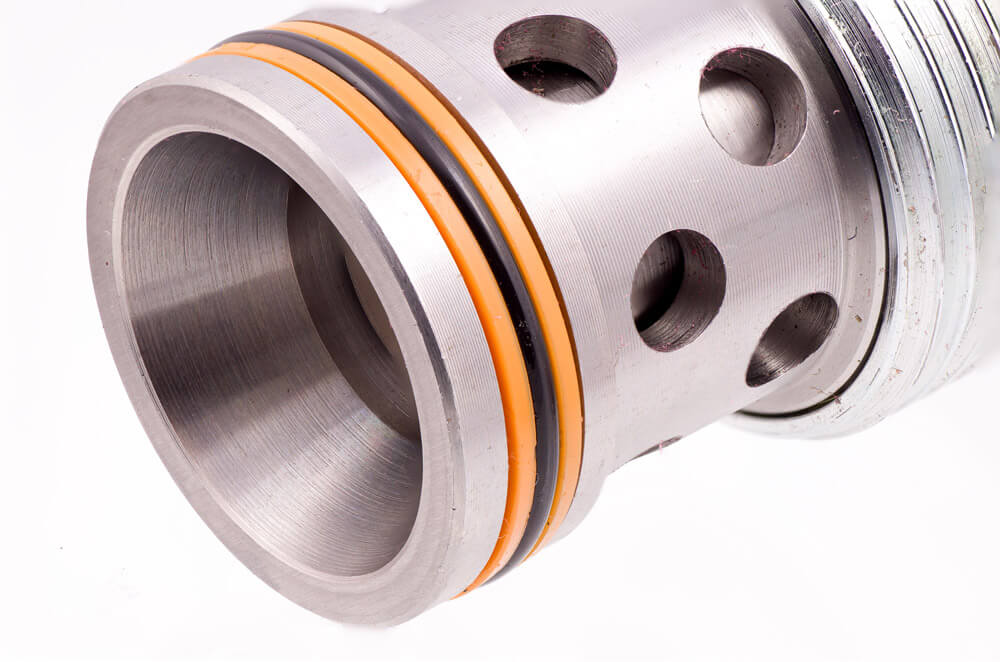

O-rings are one of the most ubiquitous sealing solutions across industries. They are typically made from rubber or elastomeric materials and have a circular or toroidal (doughnut-shaped) cross-section.

O-rings work by being compressed between two mating surfaces to create a seal, effectively preventing the passage of fluids or gasses. The O-ring’s simplicity and efficiency make it a popular choice for various applications.

Applications of O-Rings

O-rings find widespread use in numerous industries, including:

- Hydraulics: Hydraulic cylinder seals and pump seals

- Pneumatics: Pneumatic system seals and connectors

- Automotive: Engine seals, brake systems, and air conditioning systems

- Plumbing: Faucets, pipe connections, and water treatment systems

- Aerospace: Aircraft fuel systems and hydraulic systems

Advantages of O-Rings

O-rings are beneficial because they are affordable and versatile. This makes them better suited for dynamic applications. Their round cross-section ensures a consistent seal, even when movement or pressure changes occur. They are also effective in preventing leaks in high-pressure and high-temperature environments.

O-rings are well-suited for applications where the sealing surface is a cylinder, shaft, or pipe. They’re commonly used in dynamic sealing applications, such as hydraulic systems, pneumatic systems, and rotary shafts.

In these situations, the O-Ring would work between the two moving parts, helping keep them lubricated and preventing leakage and excessive wear and tear.

O-rings are also used in static sealing applications, including flanges and valve connections.

What Are Lathe Cut Gaskets

Lathe-cut gaskets are a type of static sealing solution typically made from a wide range of materials, including rubber, cork, and various elastomers.

They are cut from a cylindrical piece of material using a lathe machine, hence the name “lathe cut.” These gaskets come in various shapes, sizes, and thicknesses, making them versatile.

Applications of Lathe Cut Gaskets

Lathe-cut gaskets are commonly used in various industries, including:

- Automotive: Engine gaskets and transmission seals

- Plumbing: Pipe connections and valve seals

- Aerospace: Aircraft engine components

- Chemical Processing: Sealing tanks and vessels

- Electrical: Insulation and electrical enclosures

Advantages of Lathe Cut Gaskets

In many cases, lathe-cut gaskets are seen as an alternative to O-rings. They are built to function in many of the same applications as O-rings.

However, they also have specific applications where O-rings are not effective. Lathe-cut seals are a great option for static applications. These gaskets excel in static sealing applications with little movement or pressure fluctuation.

They create reliable seals between flat surfaces, making them suitable for flange connections and similar applications. However, they may not perform as well in dynamic or high-pressure scenarios as O-rings.

Related Post: The Difference Between Lathe Cut Gaskets and Molded Alternatives

Due to their simplicity and adaptability, lathe-cut gaskets can be used in various industries, including plumbing, automotive, and industrial equipment.

Contact Coating Systems For More Information

If you need a sealing or gasket decision, don’t make the mistake of thinking that O-rings and lathe-cut gaskets are the same or, worse, interchangeable. Picking the right gasket can keep your machinery healthy, so you want to ensure you put in the effort in your search. For more information on gaskets, call Coating Systems at 1 (800) 593-7754 or contact us online today.