Coating Systems has been serving industrial clients for 40 years, and in that time we have developed a deep and detailed understanding of coating materials, machine lubrication, industrial applications and more. Not only that, but we consistently take a proactive role in working with our clients on their projects, making sure that they get off to a running start.

Our belief in high-quality, durable products and attentive and understanding customer service has helped us to last for so many years. This is not to mention the range of products we offer, from materials such as Emralon, Xylan, Tm001 and other coating options, to innovative and state of the art services like dip-spin coating and custom applications.

In our Coating Systems blog, we aim to educate you on some of the finer details of the products and services we are able to provide – from the lubricants and materials that coat and reinforce your parts and equipment, to the more complex methods of coating and protecting equipment.

Related Post: Which Products You Should Coat with Emralon Tm001

By looking into the history, common uses and pros and cons of these products, we can help you stay informed and decide that much easier which is right for your project. In this entry, we’ll be looking into Emralon – so if you’re new to the industry, or just curious, read on to find out more.

What Is Emralon?

Emralon is a fluorocarbon dry film lubricant. A fluorocarbon refers to a compound created by replacing one or more hydrogen atoms in a hydrocarbon with fluorine atoms to imbue or enhance specific properties.

What Are the Benefits?

One of the key benefits of Emralon and this type of coating, in general, is adaptability. It can be used to coat wood, metal, rubber, plastic and even glass. For moving parts, this coating helps them last longer and resist wear, and comes as a liquid concentrate that can be diluted depending on the requirements of its use. Other benefits include:

- Strong surface adhesion

- Only requires a thin layer

- Translucent

- Clean and simple application

- Cures at room temperature

- Creates a hard surface

- Excellent lubrication ability

- Lasts for a long time without losing strength.

Where Is It Used?

Common applications and uses for Emralon include:

- Moving parts in furniture such as hinges

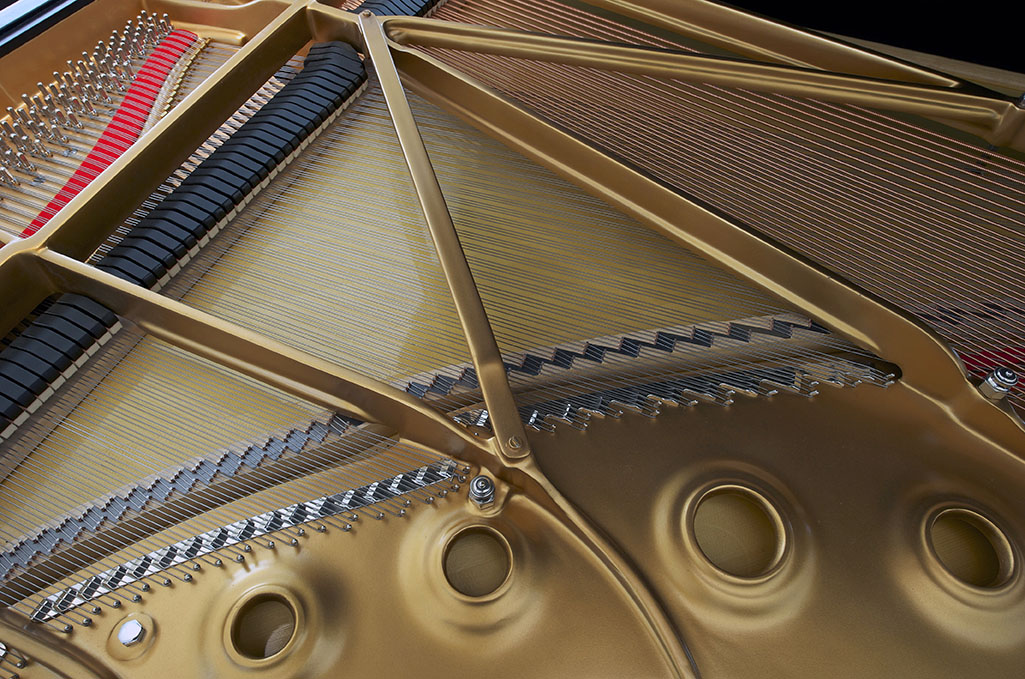

- The moving parts on the interior of a piano

- Plastic hinges on storage bins

- Guides and moving parts on windows.

These are just a few examples, but this coating material option is great for a wide variety of wood, plastic, rubber, glass or fabric-based applications.

Emralon and Other Coating Options

Hopefully, this blog entry has given you some additional insight into Emralon, and the benefits it offers as an industrial coating option. Our blog is just for informational purposes, and there are many other more technical details when it comes to coating and lubrication that will be beneficial or not depending on your project, so it’s always best to speak to a professional. If you need the best in industrial applications, contact Coating Systems today.