Coating application methods are an important part of the coating process. Finding the right coating solution is only the first step. If you don’t utilize the proper applications method, not only will your coating be in danger of not being effective, but it could also do damage to your equipment. One of the application methods that is growing in popularity is dip-spin coating. In today’s blog post, Coating Systems will take a look at how exactly the dip-spin coating process works.

Related Post: What Makes Dip-Spin Coating Preferable to Other Coating Methods?

Cleaning

In all coating solutions, regardless of the method, the cleaning process will be key. Without cleaning the items or equipment being coated, the coating can easily become contaminated and lose effectiveness. Your parts and equipment must be cleaned and pretreated before they head to the application phase. If your parts are not completely clean, the coating will be contaminated, and it will either damage the surface itself or render the coating ineffective.

Application

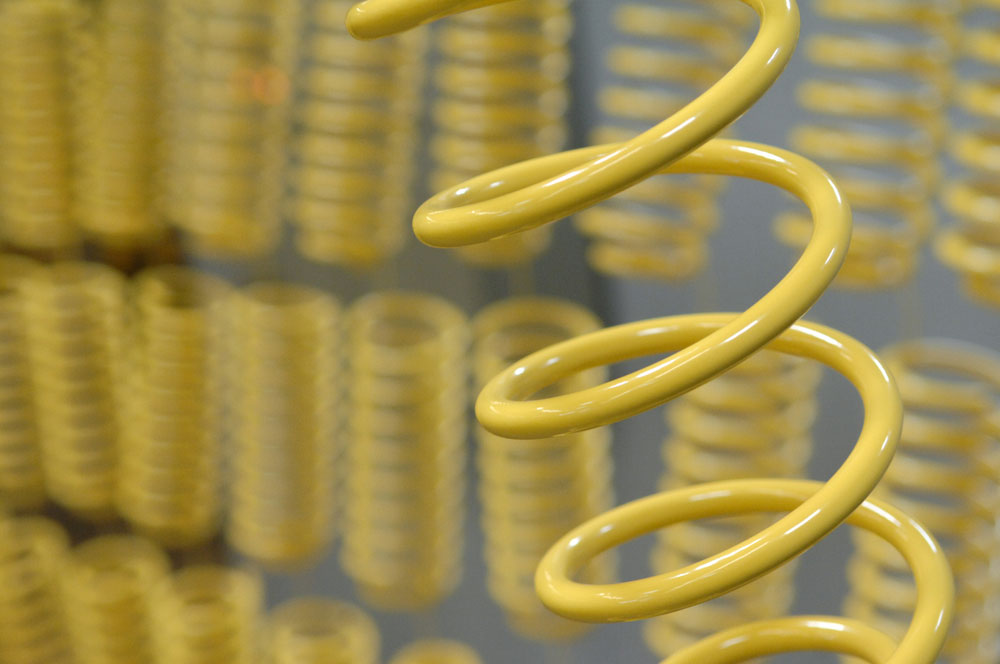

The dip-spin coating application process might actually be the simplest and easiest application process. Once all of the pretreatment coatings dry, your parts will be placed in a wire mesh basket and submerged into whatever coating solution is being utilized for your parts. These coating solutions can include fluorocarbons, ceramic metallic systems, and waterborne systems, as well as zinc-rich coatings.

Once the parts are dipped into one of those coatings, they are spun at a high-speed, removing excess coating.

Curing

The curing process is equally important to the application process. For dip-spin coating applications, equipment and parts are put into a curing oven and heated to a certain temperature. This process typically takes longer than the drying process and not all parts will cure at the same pace. The curing process of dip-spin coating ensures that all solvents and water have been evaporated from your coating before they are sent to their ultimate destination.

Related Post: How to Apply Spin Coating

Contact Coating Systems for Spin Coating Tips

If you are looking for a coating solution for your parts or equipment but you don’t know what method would be best, Coating Systems can help. Whether you require dip-spin coating or another specialized solution, we are ready to deliver the results you need. For more information on coating methods like dip-spin coating, give us a call at 1(800) 593-7754 or contact us online today.