Coating Systems, Inc. has over 40 years of experience helping all kinds of industries, from aerospace to irrigation, with their coating solutions. With coatings such as Xylan, Emralon, TM001, and more, we are able to address all kinds of industrial lubricant concerns. Our dry film lubricants reduce overall wear on o-rings and machine parts, thus extending their lifespan. This extended lifespan means that your operations will run more smoothly and for longer times, ultimately yielding a better functioning business.

We also offer the polymer blend ETFE, which consists of both ethylene and tetrafluoroethylene. As a coating, ETFE offers a number of awesome benefits, including heat and chemical resistance, a low friction coefficient, electrical insulation, and more. It is virtually inert and – due in part to its low friction coefficient – it does not easily take on oils or water.

Related Post: ETFE for Construction

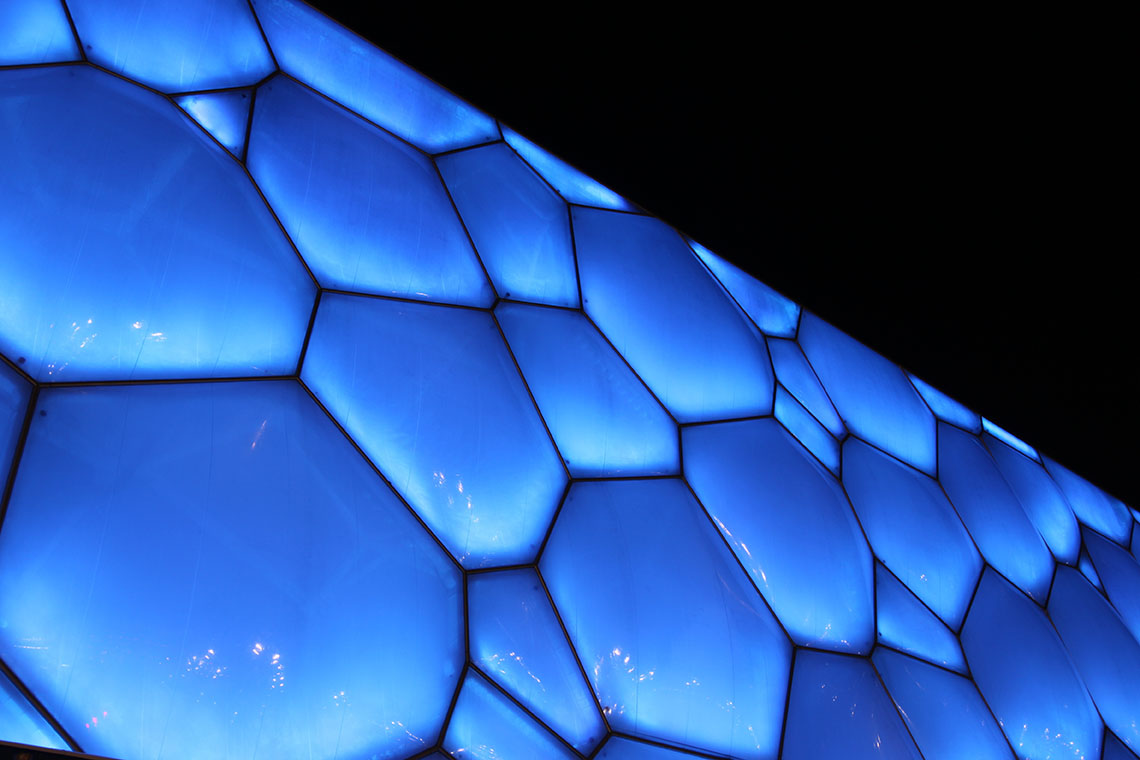

Recently, ETFE has begun to show promise as a construction material. In fact, ETFE is the material that made possible Beijing’s “Water Cube,” the aquatics center used for the 2008 Olympics. As a material, ETFE offers many of the same properties it does as a coating, but with some slightly different benefits.

Below, Coating Systems, Inc. explains some of what makes ETFE such a remarkable material.

How is ETFE Used?

Because ETFE is a plastic, it is able to be stretched, melted, and inflated. These properties are part of what makes it so useful as a glass substitute. Unlike glass panels which must be fitted into frames and which can shatter from an abrupt impact, ETFE can stretch many times its original length and retain its elasticity. It can fracture, but because of its tensile strength, it will not shatter like glass.

ETFE, A Sustainable Glass Substitute

ETFE is well-suited as a glass substitute for a variety of reasons. As noted above, ETFE need not be set into frames. Rather, it is “thermoformed” by heating it and fusing it with other layers of ETFE. When these layers are inflated and supplied with sufficient air pressure, they can maintain their structural integrity over large areas. In fact, ETFE does not even lose its shape when heated, which makes its installation easier than glass.

ETFE is also as transparent – if not more so – than glass. Unlike glass, ETFE will retain this transparency for many years without warping or yellowing as windows will.

It is sometimes said that ETFE is a self-cleaning material, which largely has to do with its very low friction coefficient. Because of this, materials such as dirt will not stick well and can easily be washed off with water.

Learn More about ETFE with Coating Systems, Inc.

ETFE is clearly more than a useful coating. And what we’ve detailed here are only some of the awesome things about this polymer. To learn more, keep your eyes on this blog, where we’ll be sure to say more about ETFE in the future. For samples of Coating Systems’s work or to contact us for a quote, give us a call! Alongside ETFE we also offer FEP, MOLYKOTE®, Rilsan, Kynar, Halar, Xylan, and more. Let us provide you with the coating solutions you need!