At Coating Systems, we offer a variety of professional and high-quality lubrication solutions for industrial applications. One of the most effective and innovate options for some specific tasks is spin coating.

You may have heard the term “spin coating” in relation to industrial machinery, but are not familiar with what exactly it is. We aim to inform our clients in order to help you make the best decision for your business. In this blog, we break down some of the basics and uses for spin coating.

Related Post: How to Apply Spin Coating

When Did It Start?

The first patent for this type of coating was filed at the end of the 1970s and finally published in 1981. Since the initial patent publishing, a long list of patents followed that offered modified versions of the original method.

This includes variations such as uniformly coating substrates and lower surface energy templates, among countless others. As with any method in industrial machinery and engineering, types of coating for different pieces of equipment is always benefiting from new innovations and ideas, breaking down the basics of how it’s done and introducing new ideas to make things more efficient.

The Simple Idea Behind Spin Coating

The idea behind this method of applying coating is to do it as evenly as possible through rotation. The substrate is coated with a solution made of whatever material is required, moleculerized in a solvent form.

Related Post: Common Problems with Improper Spin Coating Technique

This is then spun at a high speed, ejecting the most of the solvent, with the remainder plasticizing on the surface. This film of solvent that is left finally dries and the molecular material is left as the coating on the substrate. The speed of the spin is what creates an even coat through centripetal force.

How Is It Used?

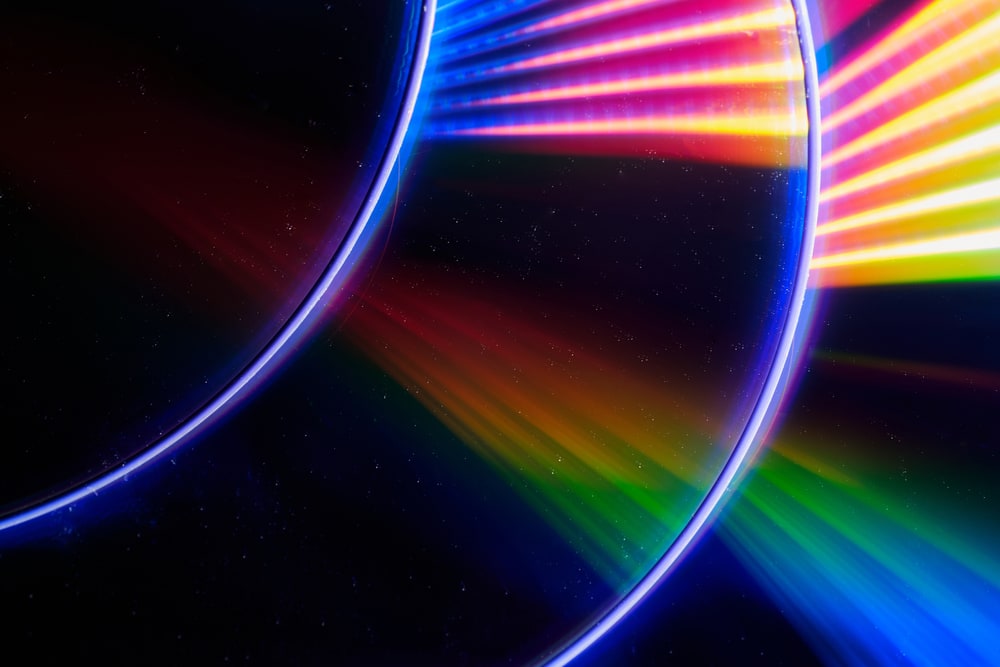

There are a wide variety of different applications that use this type of coating. Examples range from extremely small substrates to CDs, DVDs, and Blu-Rays, to parts of large HD TVs.

Different components in a large range of electronic and mechanical processes, such as synthetic metals, nanomaterials, insulators and more are frequently used in — or coated through — the spin coating method.

Spin Coating Solutions at Coating Systems

Whether you are looking at options for spin coating, or you are looking for other types of coating, contact Coating Systems today. With our experience and knowledge, we aim to help you make the right choice, and will help you at each step to achieve efficiency and safety in your industrial environment. Take a look at some of the other coating and lubrication options we offer, from Xylan to Emralon or Tm001.