At Coating Systems, Inc, our customization options allow you to have a custom formulation made for your products, which will greatly set you apart from the competition. We use the latest state-of-the-art equipment to ensure that your products get a quality coat and that we can offer you the fastest turnaround time possible.

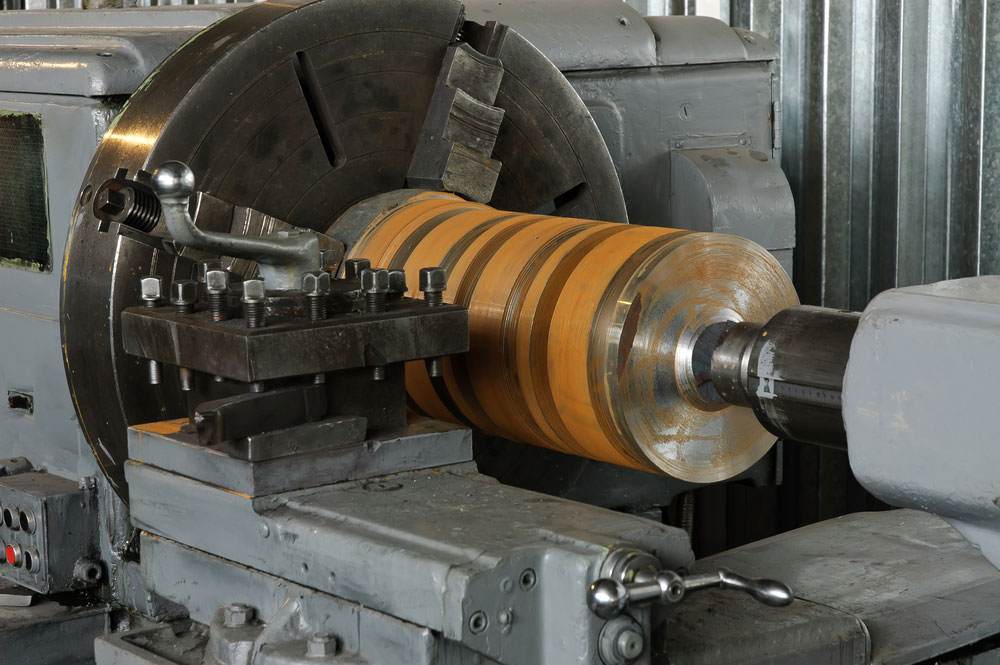

Today, we are going to take a closer look at lathe cut gaskets. Our experts will share some reasons for their use.

Cost Savings

Lathe cut gaskets can be made out of any polymer group and offer distinct cost savings for custom sizes since there is little to no tooling required in the lathe cut process. Whether you need the gasket itself to be a little thicker or you need the sealing surface to be a bit wider, both are quick and easy fixes.

Related Post: Are There Differences Between Rubber Gasket Coatings And Gasket Sealers?

Turnover and Flexibility

A major advantage of lathe cut gaskets in comparison to molded or die cut gaskets is that lathe cut gaskets require very little tooling and therefore have a quicker turnaround. Molded gaskets take longer to develop when a custom mold is required. Unlike the lathe cut development process where tweaks can easily be made, if a mold’s specifications are off even slightly, the mold must be scrapped and you’re back to square one. The die-cut gasket can also be complicated. The design process for die cut gaskets is based on the thickness of the sheet material. Special custom thickness can be costly depending on the size and tolerance you require.

Seal Longevity

A lathe cut gasket’s rectangular or square cross-section offers a larger sealing surface compared to that of an O-Ring. A lathe cut gasket with a wider sealing surface can also provide better resistance and longer-lasting performance over an O-Ring. Lathe cut gaskets are also more advantageous in static applications.

Works in All Environments

Whether your lathe cut gasket is used for outdoor applications, dynamic applications, food grade applications or something else, lathe cut gaskets are a great choice. They are great for static applications, meaning applications including immovable parts. Its rectangular or square cross-section offers a larger sealing surface.

Related Post: Coating Systems Explains Lathe Cut Gaskets

Contact Coating Systems

At coating systems, we are committed to providing you with the best coating solutions on the market. We want our customers operating on the highest possible level and we provide excellent and expert customer service to meet all of your needs. To talk to one of our professionals about how we can help you, contact us today.