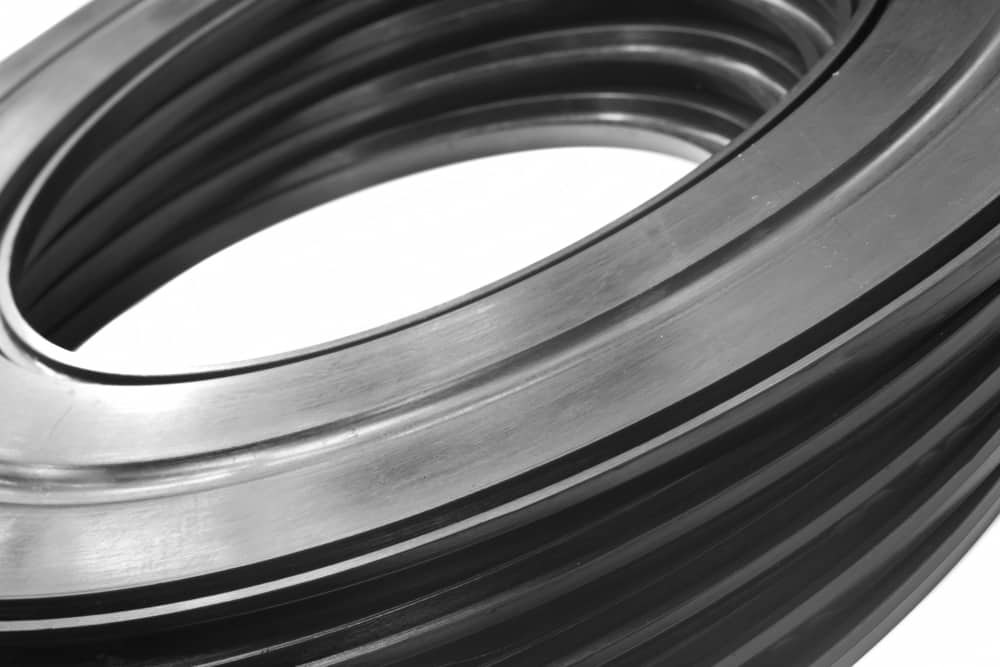

What Is Rubber Packing, and What Is It Used For?

Coating Systems has been providing customers across a wide range of industries with the best in industrial, high-quality coating solutions since 1975. From powder coating to spin coating, we have extensive experience in the meeting demanding standards of durability and reliability. We can also provide you with important information about products and materials that can improve your processes. In this blog, we will go over the basics of rubber packing – what it is, and what it is most often used for. If you are wondering about the benefits of rubber packing in industrial applications, read on to find out more.

Types of Material

Rubber packing comes in a variety of types, all of which offer their own benefits for specific applications and uses.

Related Post: Coating Systems: Examples of Polymers

Ethylene Propylene Diene Monomer (EPDM) Rubber

EPDM is a durable elastomer that is used in processes where there is exposure to acids, brake fluids, and weaker alkalis. EPDM has a high resistance to the elements, especially ozone and harsh sunlight, and is ideal for outdoor uses.

Buna Nitrile (NBR) Rubber

NBR is typically used in pneumatic and hydraulic applications. This is an oil-resistant rubber. It’s the perfect option for petroleum hydraulic fluids that offers high tensile strength and strong resistance to abrasion.

Neoprene Rubber

Neoprene is a synthetic rubber that offers high resistance to oil, ozone, and sunlight. It is also resistant to oxygen, ammonia, and a wide variety of industrial fluids. Two applications which often use Neoprene rubber packing are refrigeration units and gaskets that are exposed to seawater.

Silicone Rubber

Silicone is another common type of rubber packing used to seal gaskets. Silicone can withstand extremely high temperatures, which is a vital benefit when it comes to industrial applications. It is also chemically inert, which is a major benefit for food processing applications.

Fluoroelastomer (Viton) Rubber

Viton-based packing is resistant to a variety of harsh, caustic materials such as fuels, oils, mineral acids, aliphatic hydrocarbon fluids, and lubricants that can dissolve other types of rubber material. It also has a high resistance to temperature and is resistant to mold.

Common Uses

Common uses for these materials include shipping vessels, which benefit from a high resistance to saltwater corrosion. More day-to-day items that benefit from properly applied rubber include common garden hoses, larger and more durable fire hoses, chemical hoses, industrial refrigeration and gaskets used in a wide variety of heavy duty manufacturing processes.

Related Post: Are There Differences Between Rubber Gasket Coatings and Gasket Sealers?

Order Rubber Packing from Coating Systems

If you need rubber packing, contact Coating Systems today. If you are looking for other options in industrial coating or sealing materials, you can find it at Coating Systems. Not only do we offer coating options for O-rings, we also provide them with rubber grommets, dye-cut seals, quad seals, caliber support bushings and much more.