At Coating Systems, we specialize in coating machine parts for a variety of industries. One machine part we often encounter is the lip seal. Known for its durability, flexibility, and versatility, lip seals are used in many types of machinery, including hydraulic systems, turbine systems, motors, and more. There are many options out there for seals. To help you pick out the right seal, we’ve created a little guide for selecting the perfect lip seal.

Related Post: Lip Seals: How Do They Work and Why Are They Important?

Why Use Lip Seals?

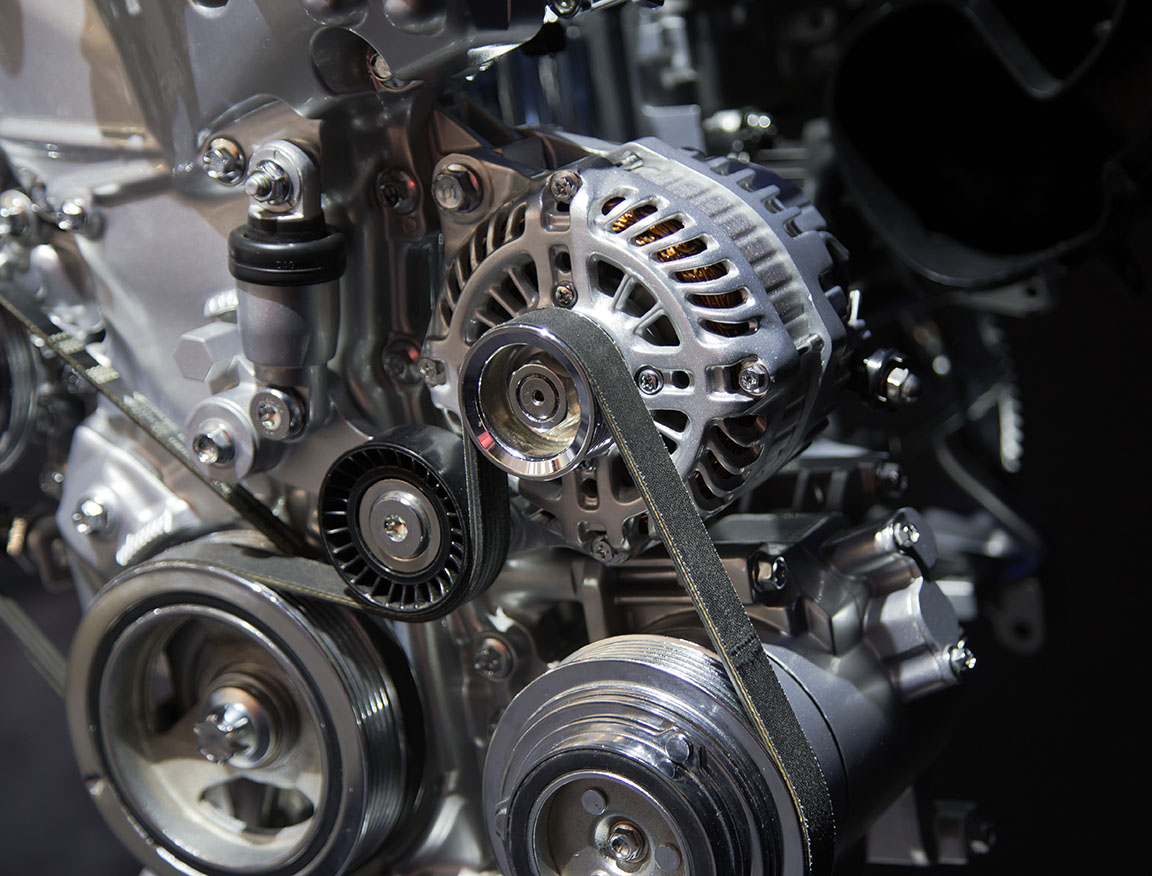

The main purpose of a lip seal is to keep lubricants within the machine while excluding contaminants from entering the machine. When installed properly, this type of sealant can last for years. In fact, these seals are often incredibly durable and can withstand temperatures up to 500 degrees Fahrenheit when made with the right material. They can also handle the unique demands of different applications and can be used in slow-moving equipment or situations that require continuous high-speed rotation.

Selecting a Lip Seal

There are many factors to take into account when you choose a seal for your machinery. First, you need to consider the temperature of the machinery: does it get extremely hot or is it operating in freezing conditions? The answer indicates what kind of material you need for your seal. The most common material for lip seals is nitrile. Nitrile is incredibly versatile and can handle temperatures of negative 40 degrees Fahrenheit to 275 degrees Fahrenheit. If you are operating at a higher temperature, you may have to use Viton. Although this material is slightly more expensive than nitrile, it can withstand temperatures up to 400 degrees Fahrenheit.

Related Post: Coating Systems Provides a Beginner’s Guide to Lip Seals

Second, you must consider shaft speed. Will you place the seal on a slow-moving part or a piece of the machine that is continuously moving at high speeds? Third, you will need to consider the amount of pressure that will be exerted on your seal. Some seals are only designed to withstand low-pressure applications. If the seal must withstand large amounts of pressure, you may have to go with a different material. Carefully consider all these factors and talk with an expert before choosing your seal.

Contact Coating Systems

In addition to lip seals, Coating Systems also works with lathe cut gaskets, rubber grommets, and other types of industrial sealants. If you are looking for a coating solution for your machinery, contact us today! With over 40 years of experience in customer service, we can help you find the type of coating that is right for you. With our state-of-the-art equipment and expertise, we will deliver a coating that is smooth, high-quality, and long-lasting. Call us today at 1-800-593 7754 to learn more!