Xylan is an extremely versatile material used in coating application on a variety of products. Its versatility allows for a large number of benefits that you can take advantage by getting this coating applied to your product. Coating Systems offer economical coating services that can apply this and other coatings for an endless variety of items. Today, the Coating Systems team is discussing some of the many benefits of a Xylan application and how you can use Coating Systems to improve your products.

Five Benefits of Xylan Coating

#1 – Very low friction coefficient that lasts

One of the main benefits of Xylan coating is how low the coefficient of friction of this dry lubricant is. Depending on the line of coating, your friction coefficient can be as low as .02. This makes it perfect for application to products that need long-term lubrication. One of the reasons that Xylan is used in the automotive industry so much is because of the success of it as a lubricant on automotive parts like clutch and brake shift bearings. Reducing friction helps to extend equipment life that conventional lubricants that dry out are unable to do. Many automotive manufacturers also apply this coating to the rubber channels that windows pass through when raised and lowered. The extreme reduction of friction helps to eliminate noise and prevent the glass from sticking during freezing weather.

Related Post: Coating Systems Explores the Damage Done by Friction

#2 – Available in virtually any color

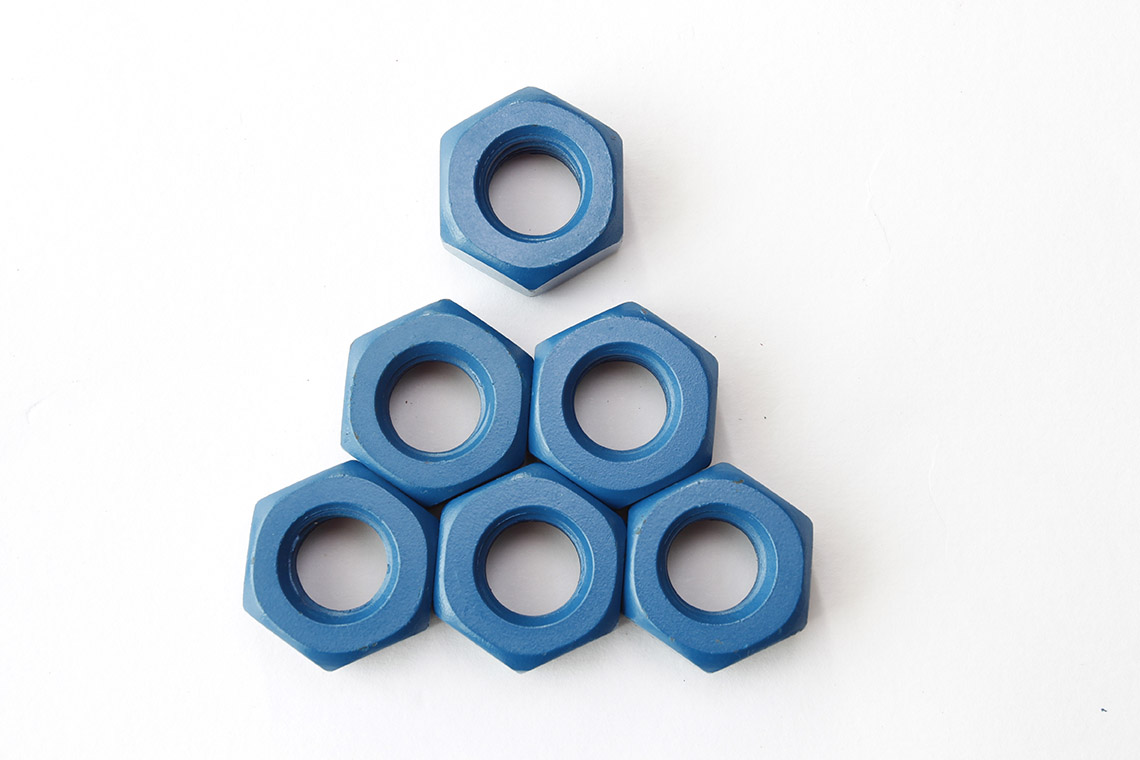

Xylan coatings can be custom matched to virtually any color requirements by Coating Systems. This allows you to meet Pantone or RAL color standard requirements for your product. Many clients use the wide range of available colors to help differentiate products. For instance, coating different o-rings with particular colors helps to allow categorization when shipping or assembling.

#3 – Excellent adhesion to most surfaces

Many types of PTFE coatings are unable to stick to some surfaces, but Xylan coatings have excellent adhesion to nearly every surface. One of the reasons this coating has become so popular in the engineering industry is its unparalleled adhesion.

Related Post: Uses of PTFE: Adhesives and Chemical Mixing

#4 – Thin, yet durable application

One of the best examples of Xylan versatility is how thin the coating can be applied. Using just a thin film can allow a product that does not have much room a coat to obtain the right surface properties without vastly changing the size of the product. In addition, it is a long-lasting, durable coating. Even a very thin layer can last longer than many other coating products.

#5 – Resistant to heat, chemical, and corrosive wear

Xylan is designed to resist high temperatures, chemical, and corrosive wear. This coating is a mainstay in oil and gas industries because of its ability to stand up to these extreme environments.

Contact Coating Systems for Your Coating Needs

If you have a product or industry that could benefit from Xylan or any of our other coating products contact Coating Systems today. We have the experience necessary to match you with the coating that will fit your needs and goals. Call us today at 1.800.593.7754 or email us at sales@coatingsystems.com today!